With the 3DPro® Powder Dry Cabinet, the powder can be reliably supplied to the production process in a consistently high quality.

The small particle size of the powder and the resulting large surface area lead to adsorption of moisture and oxygen from the surrounding atmosphere and contamination of the material.

The 3DPro® Powder Dry Cabinet enables the storage of metal powders for additive manufacturing in a controlled and inert atmosphere, realized by a continuous purging process of the storage cabinet with high purity gas.

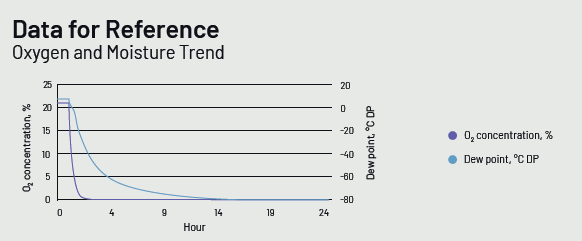

The integrated oxygen and humidity sensors, in combination with the built-in heating system, allow the user to precisely adjust the storage atmosphere.

R&D (Research and Development)

Constant powder quality through oxygen and moisture control:

-Oxygen and humidity sensors for continuous monitoring of the atmosphere in the cabinet.

-Integrated heating system in the back wall.

-Status detection of the door.

-Configurable tarfet value for oxygen and humidity via digital touch panel display.

Latest IoT technology integrated:

-The fully automatic inert gas flow control makes it possible to reach a preset oxygen and/or humidity level in a short time and with minimal gas consumption.

-High-efficiency flow control system with high-quality mass flow controller.

-3DPro® Link telemetry system for data monitoring from customer PC or other smart-devices (service contract required) - 7-inch full-color touch panel display.

Safety:

-Emergency stop switch for disconnecting all circuits.

-120 kg max. load per shelf.

-Total of 5 shelves, 4 of which are height adjustable.

-Before door opening, air purge function to minimize the risk of asphyxiation.