Freezing and chilling cryogenic solutions

Cryogenic, best way for freezing your product. Higher quality, higher production rate, higher performance and flexibility. Our wide range of solutions fits any industrial process while adapting to the type and size of the product.

"Ad hoc" solutions

Reduction of losses economic impact, in the same space as traditional tunnels.

Reduction of losses economic impact, in the same space as traditional tunnels.

Protecting coat.

Not continuous cabinet.

Not continuous cabinet.

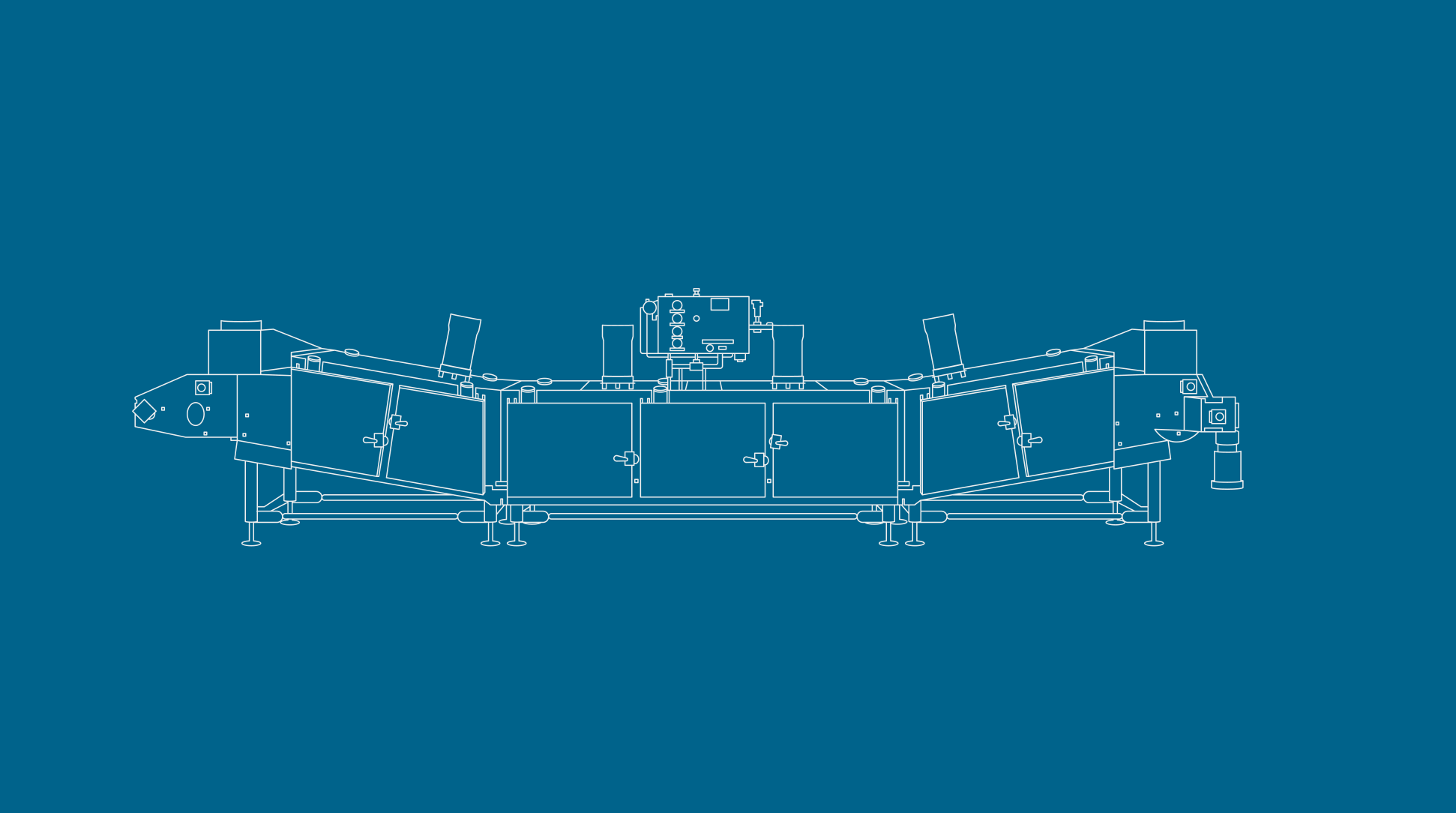

Cryogenic cabinet

Adapted to your rhythm.

Work with LIN or LCO2 and discover the versatility of the gases in our cryogenic equipment, capable of meeting production needs in a wide range of values.

Glazing

Doughs and minced meat refrigeration. IQF (Individual Quich Freezing).

Better final quality

Slowing down temperature in few time.

Freezing

Chilling.

Crusting before slicing.

Crusting before slicing.

Easy to increase

Easy to increase production capacity when needed.

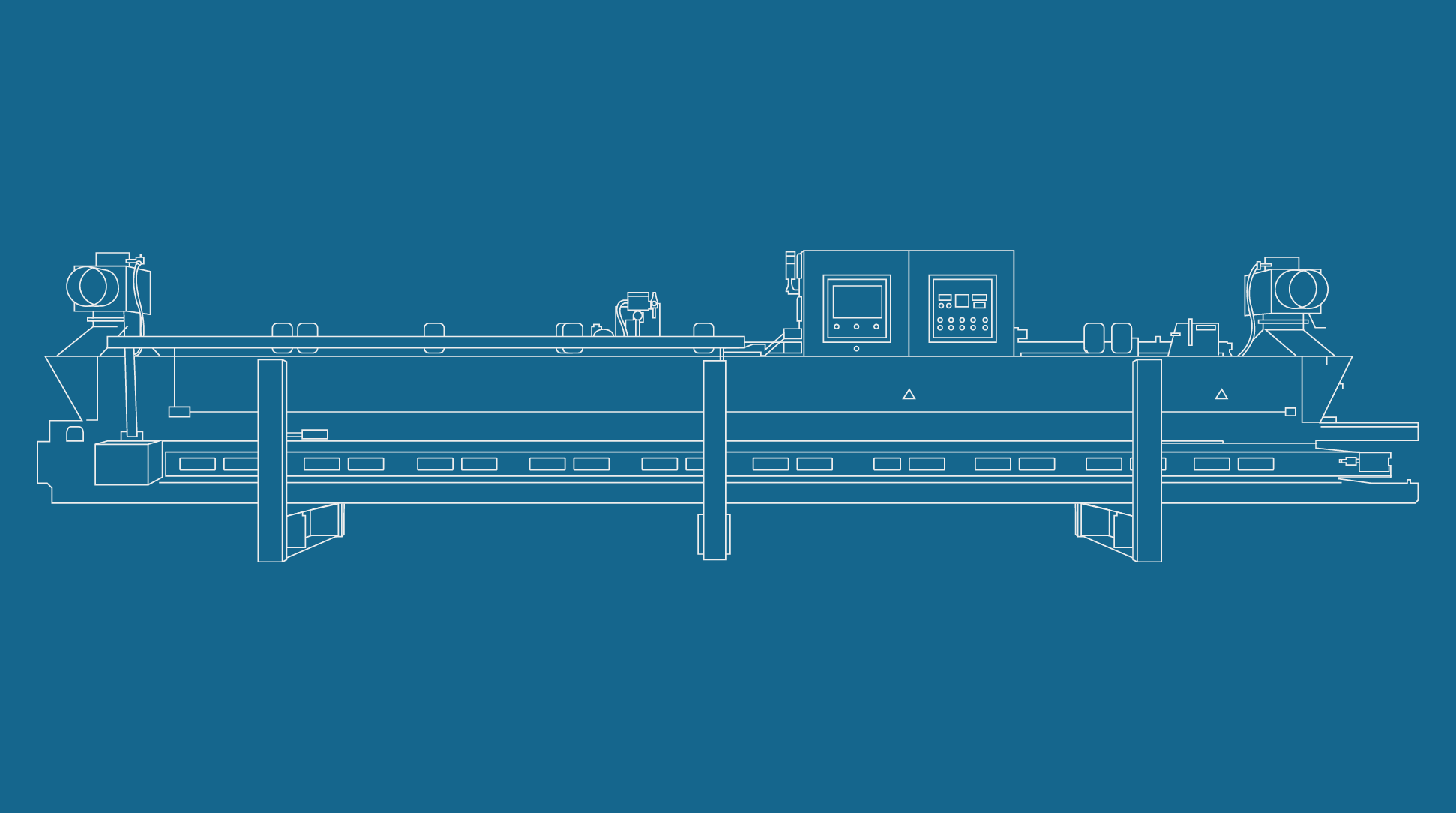

Freezing line

Best way to have a flexible and productive freezing line.

High-quality

High-quality of final product.

Better quality

Better microbiological quality. Multiple applications.

Faster process

Better organoleptic properties.

Cooling capacities

Allow reducing freezing times compared to conventional systems.

Process monitoring and control

This service guarantees the operation of the system by meeting the customer's operational needs in the design, installation, testing and commissioning phases.

At Nippon Gases we help optimise all stages of the process, analysing each case in detail to ensure maximum production performance along with supreme product quality.

-Stunning.

-Freezing.

-Wrapped.

-Blow cold.

-Mixer.

-Freezing.

-Wrapped.

-Blow cold.

-Mixer.

Meat

-Freezing.

-Blow cold.

-Mixer.

-Blow cold.

-Mixer.

Bakery

-Freezing.

-Packing.

-Blow cold.

-pH control.

-Packing.

-Blow cold.

-pH control.

Dairy

-Freezing.

-Chilling.

-Packing.

-Blow cold.

-Chilling.

-Packing.

-Blow cold.

Precooked

-Freezing.

-Wrapped.

-Glazed.

-Blow cold.

-Wrapped.

-Glazed.

-Blow cold.

Fish

Do you still have questions?

At Nippon Gases we are called “The GasProfessionals” for a reason, and it’s because we’ll be able to solve any doubt.