Competent and professional Customer Service

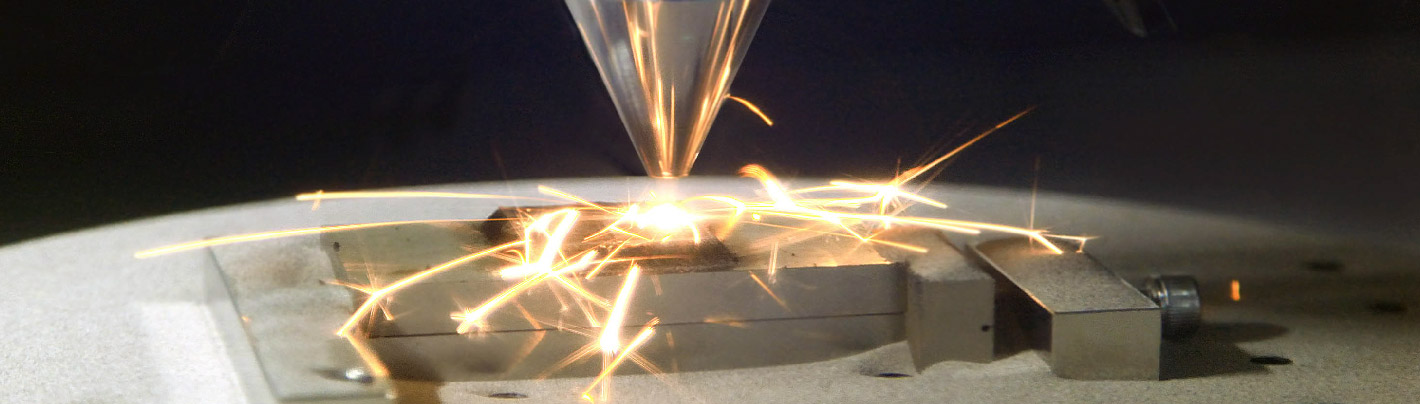

In the last few years, the 3D printing process has evolved, thanks to the development of fibre resources and a greater focus precision of the laser beam. Nevertheless, this complex process in repeatability still needs more studies and improvement to tame the lack of standards.

30

years of this technology

50

Parameters to manage

6

hour minimum for a job

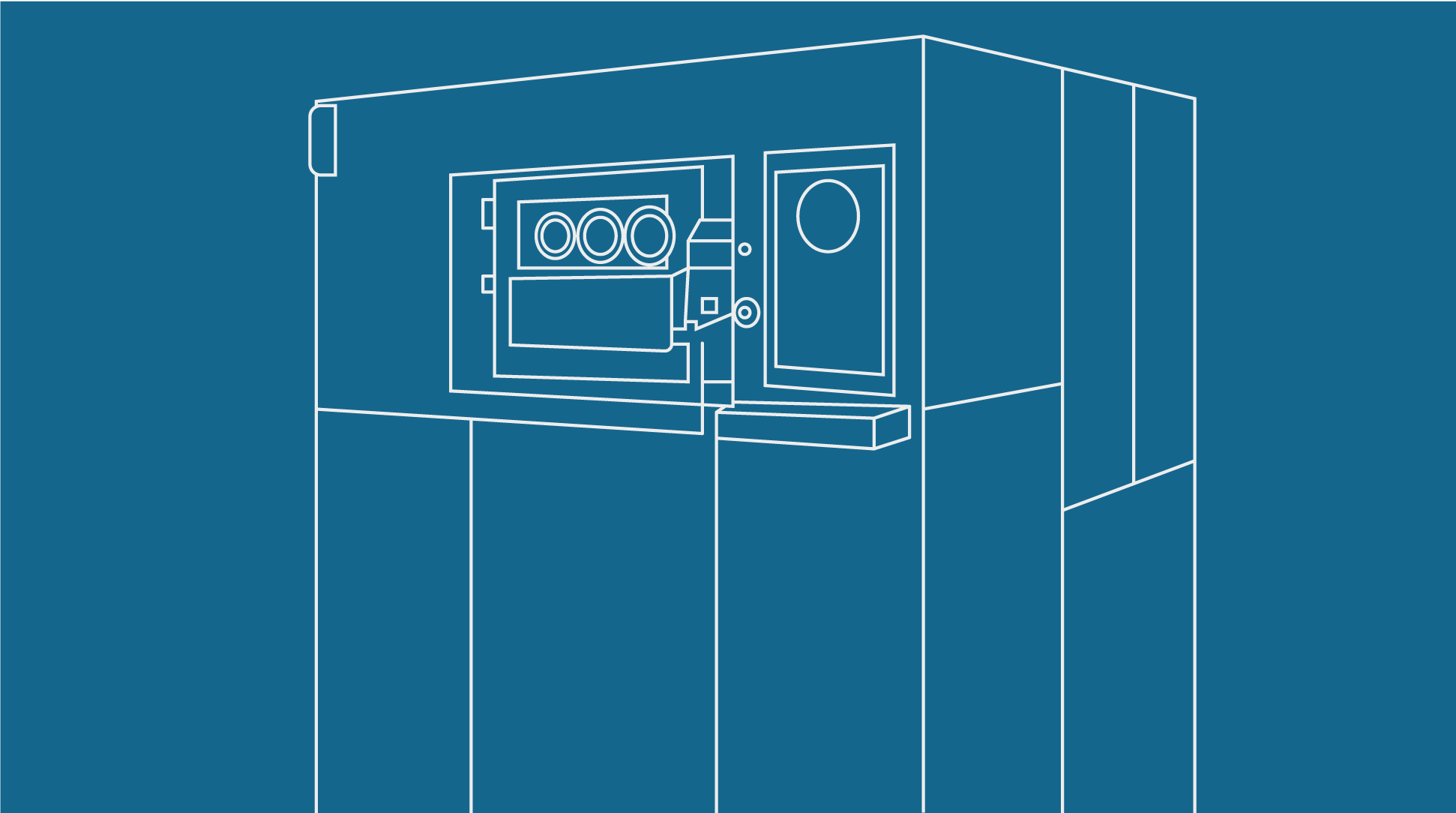

3DPro® Link helps to manage the additive manufacturing process

3DPro Link acquires all gas

management data, also through

loT technology.

The information collected is recorded during the entire

process, delivering a continuous and closely monitored

process, which will allow us to check all changes and

anomalies that may occur in real-time. So, thanks to 3DPro Link, it is possible to intervene promptly, erasing loss from the equation.

Oxygen and moisture, 3D printing enemies

In this process, oxygen is a pollutant, therefore it must be erased from the equation. Moisture too, has negative effects on this process, sometimes its presence is even more harmful than oxygen.

Nippon Gases R&D centres carried out some studies showing how these two pollutants cause imperfections in the metallurgical structure of products manufactured with the 3D printing process. Thanks to these studies, it was also possible to understand that the presence of both pollutants inside the chamber is directly proportional to the number of defects in the product. Our company has developed the 3DPro® Purifier, which drastically reduces having defective products due to oxygen and moisture presence. By eliminating these two parameters, the process can be stable and standard.

Testing