Competent and professional Customer Service

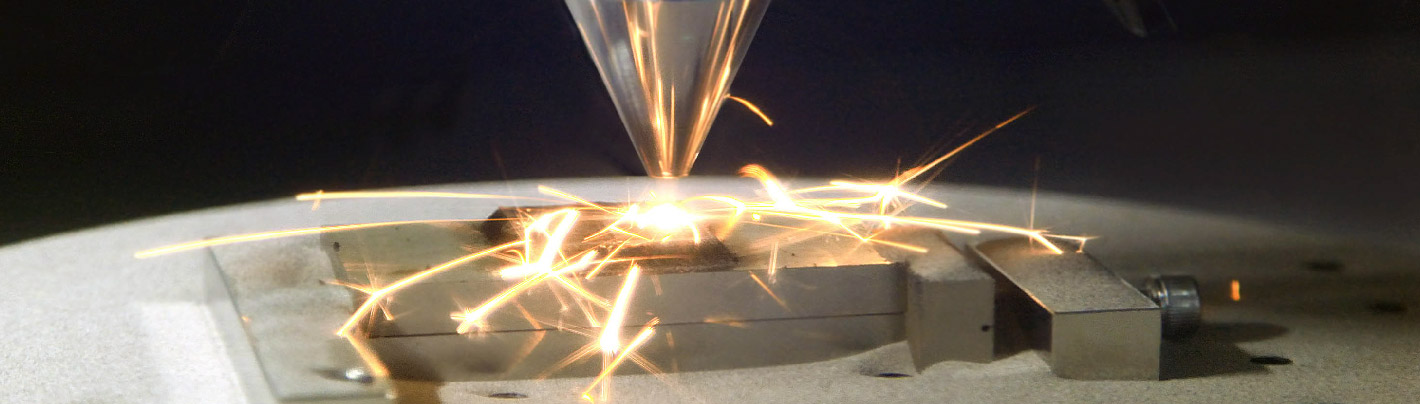

The 3D printing process has succeeded in the last few years, thanks to the development of fibre resources and a greater focus precision of the laser beam. But this is a complex process in repeatability that still needs more studies and improvement to overcome the lack of standards.

Thanks to these studies, it was also possible to understand that the presence of both pollutants inside the chamber is directly proportional to the number of defects in the product.

Our R&D centres carried out some studies showing how these two pollutants cause imperfections in the metallurgical structure of products manufactured with the 3D printing process. Thanks to these studies, it was also possible to understand that the presence of both pollutants inside the chamber is directly proportional to the number of defects in the product.

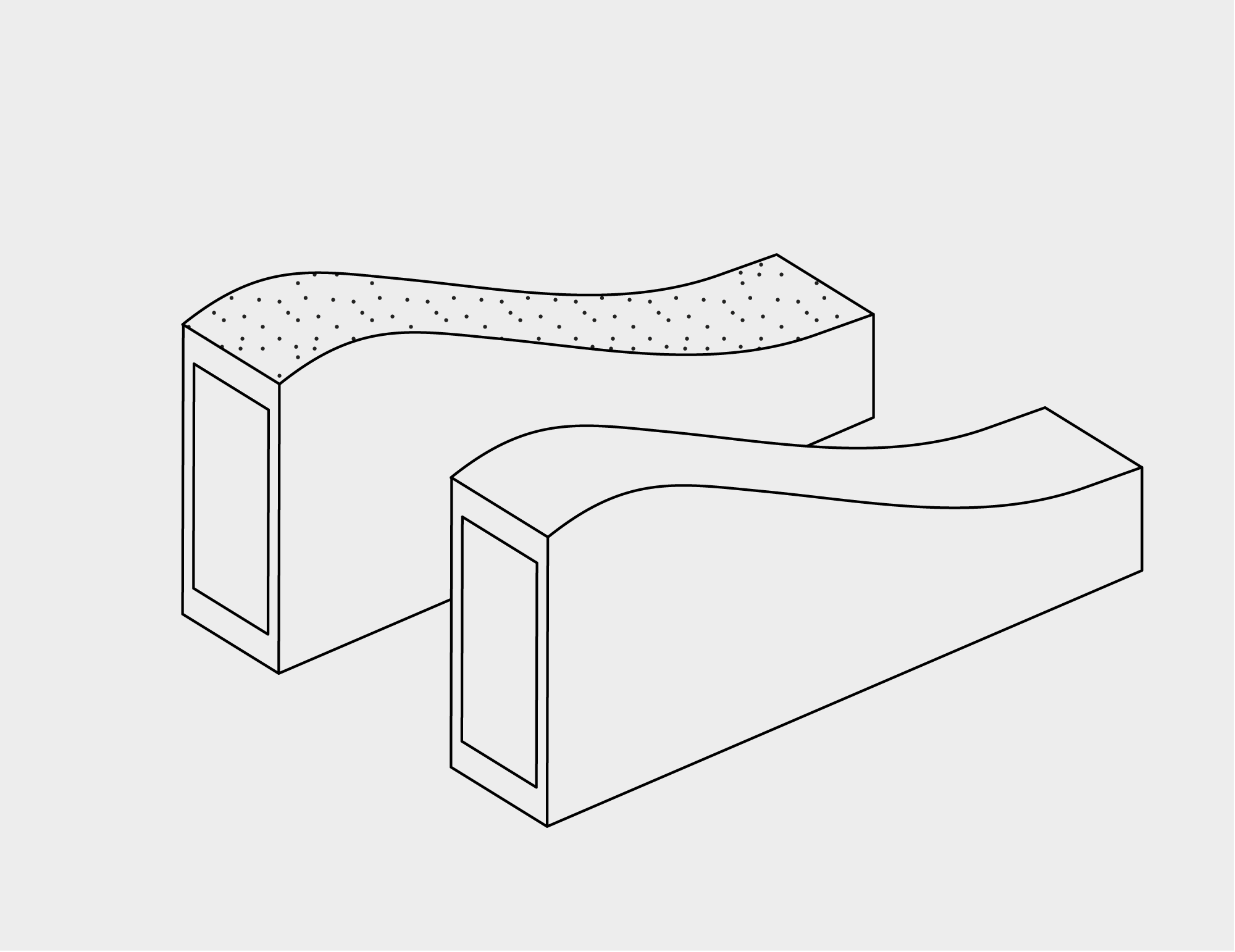

3D Pro Cabinet is a concrete solution to preserve metal powder from atmospheric contamination before the process, at the same time, it provides the necessary guarantees to obtain an effective result throughout the process.

3D Metallskåp

Nippon Gases har utvecklat ett metallskåp för att drastiskt minska defekter orsakade av syre och fukt. Genom att minska dessa två föroreningar kan slutproduktens kvalitet göras mer stabil.

Tack vare inkapslingen kommer metallpulvret att vara skyddat. Pulverkvaliteten upprätthålls genom inertisering med hjälp av ett konstant flöde av inert gas. Detta avaktiveras när skåpet är öppet och återaktiveras när dörren är stängd. Inkapslingen har också uppvärmning som tillsammans med inertgasflödet avlägsnar fukt i inkapslingen.

Testing