Pull rate increase, regen checkers repair & quality improvement

Air-fuel flame length control is feasable by using oxy-lancing technology that we can provide you.

Recuperator performance decrease.

Furnace refractory repair.

Quality improvement.

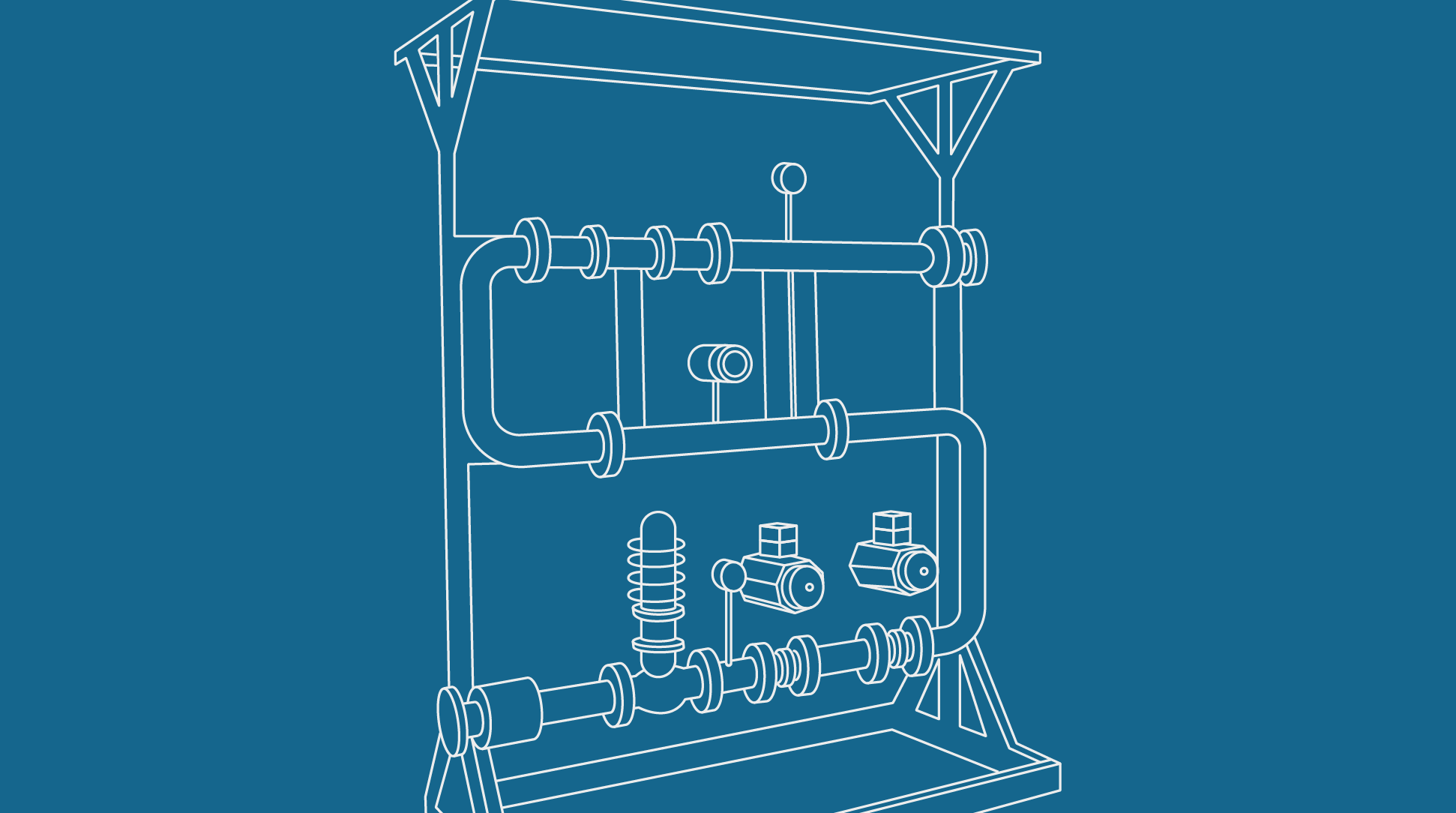

Oxy-fuel burners

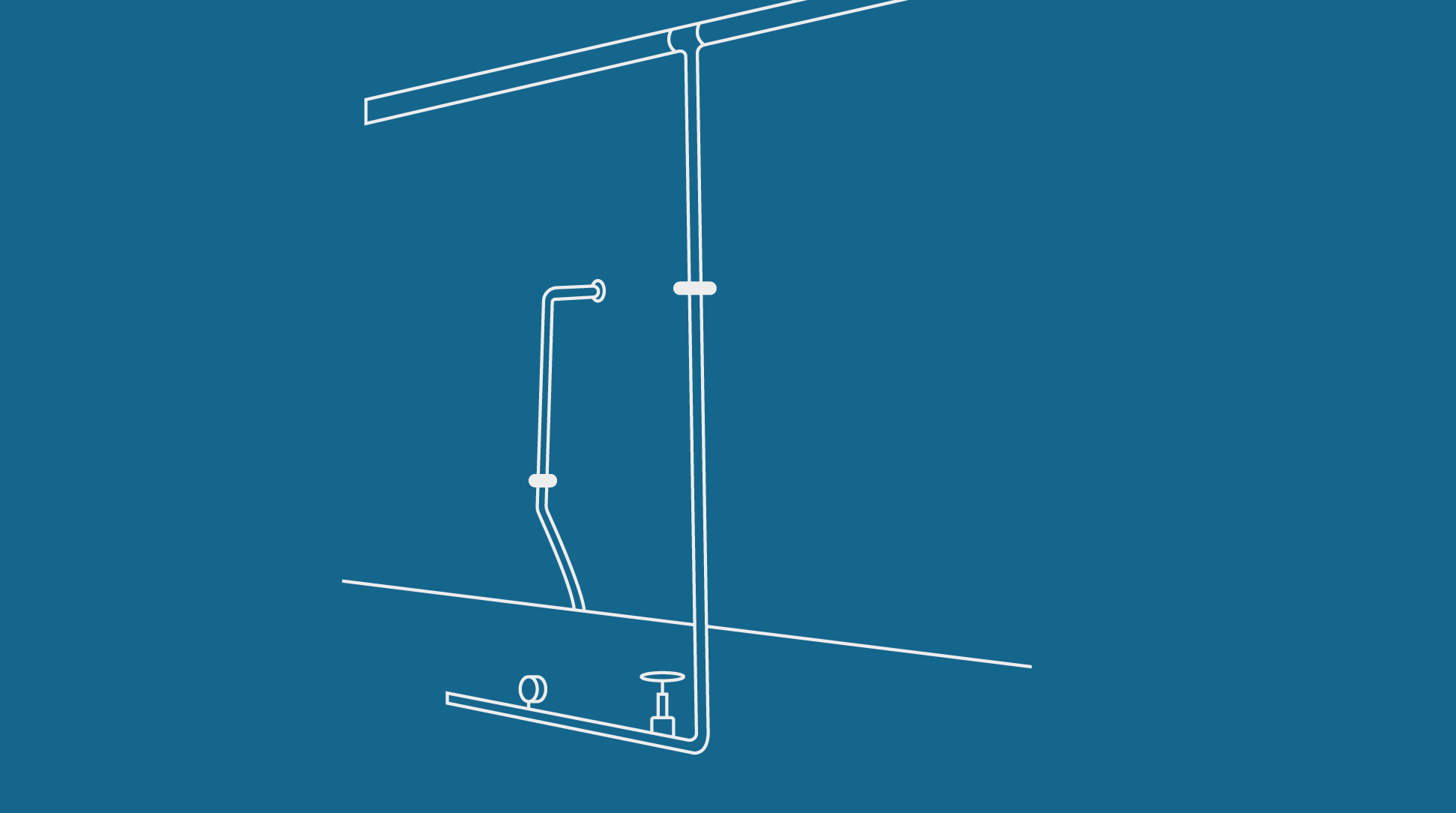

Oxygen lancing is a method where oxygen can be introduced with higher precision in locations around the air-fuel flame, where it is most required.

Oxy-lancing technology was initially used to increase the pull rate, reduce flue gas volume, and control air-fuel flame length.

Specially designed lances/nozzles can be placed next to the under-port or throught-port fuel injectors or on the side of the port.

Uses

Adjust the flame

length.

length.

Reduce pollutant

emissions.

emissions.

Lower crown

temperature.

temperature.

Improve

combustion

characteristics.

combustion

characteristics.

Reduce flue gas

volume.

volume.

Provide the

correct amount

of oxygen.

correct amount

of oxygen.

Do you still have questions?

At Nippon Gases we are called “The Gas Professionals” for a reason, and it’s because we’ll be able to solve any doubt.