Oxygen enrichment increase cupola melting rate capacity and reduce coke rate

Cost-effective technology to improve melting rate, reduce coke rate, increase carbon pick-up and improve temperature control.

All kinds of solutions.

Full range of equipments.

Designed to meet the needs of each client.

Uses

Increase

melting rate.

melting rate.

Minimise

emissions.

emissions.

Improve temperature

control.

control.

Maximise

productivity.

productivity.

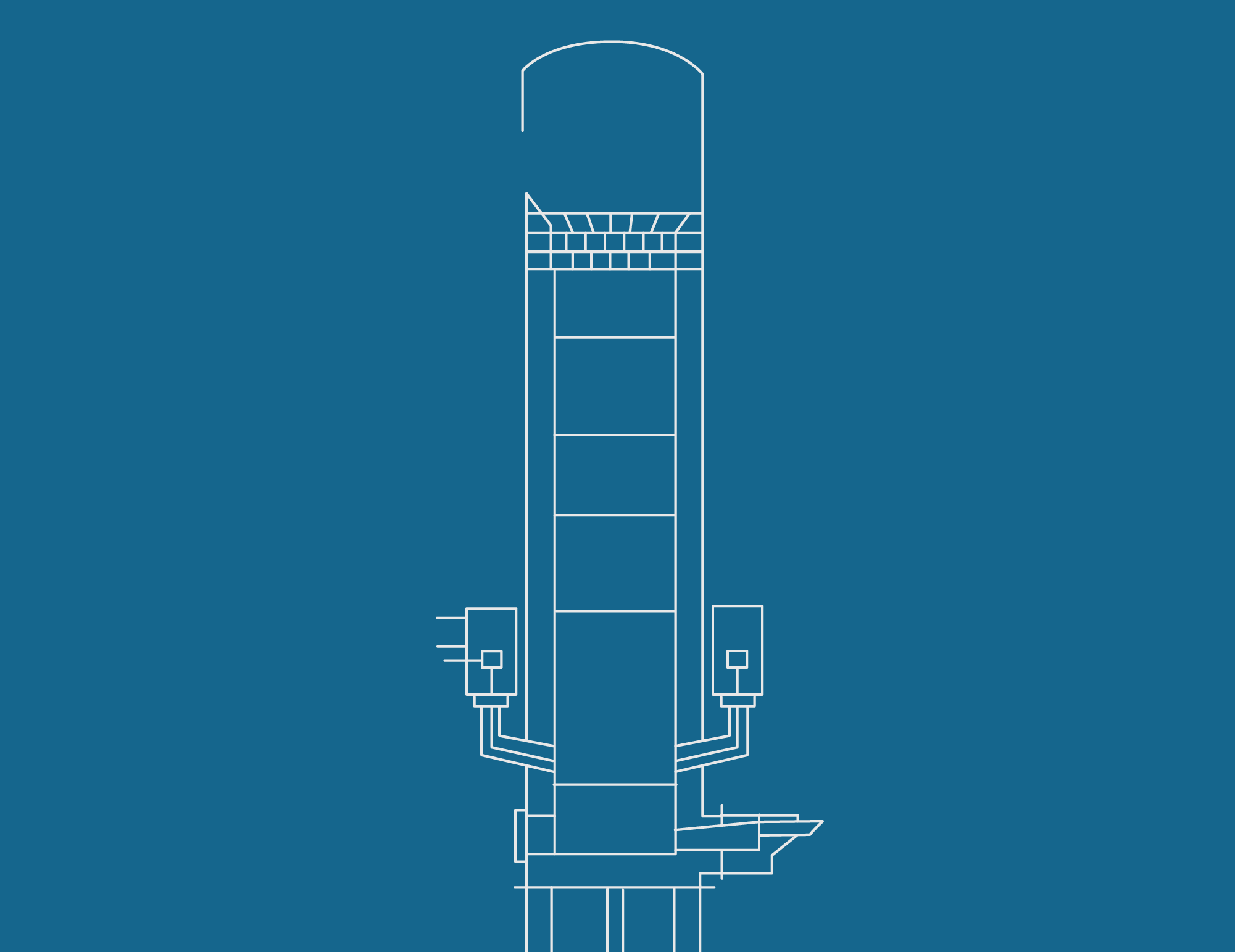

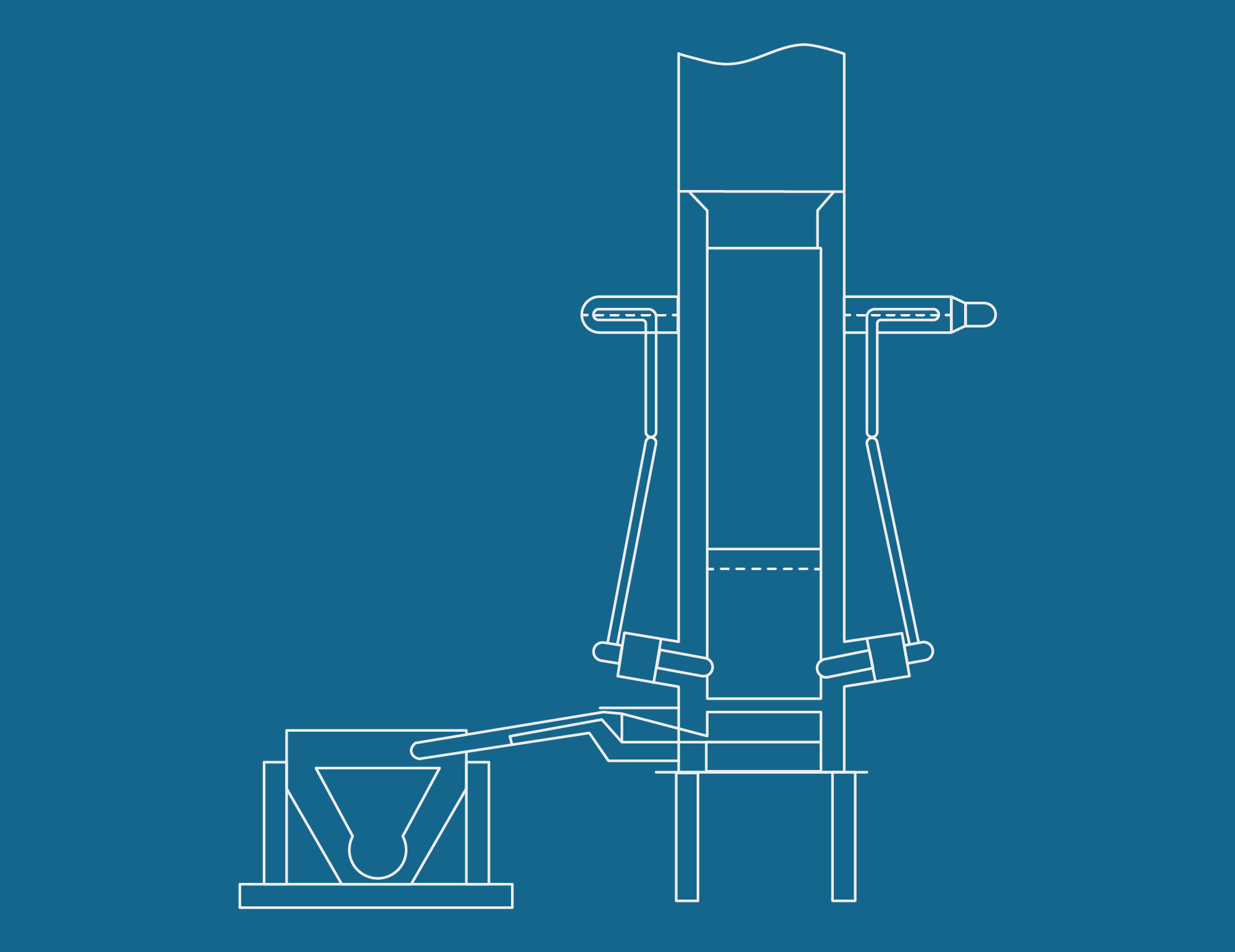

Oxygen enrichment for cupolas

Compelling technical alternative to provide the cupolas with the capacity to better manage temperature control.

Offers a low cost, low maintenance option that can be installed on most of the cupolas improving their melting rate, the silicon yield and reduce their coke rate.

Do you still have questions?

At Nippon Gases we are called: “The Gas Professionals” for a reason, and it’s because we’ll be able to solve any doubt.