The guarantee to convey high-quality gas to the 3D printer

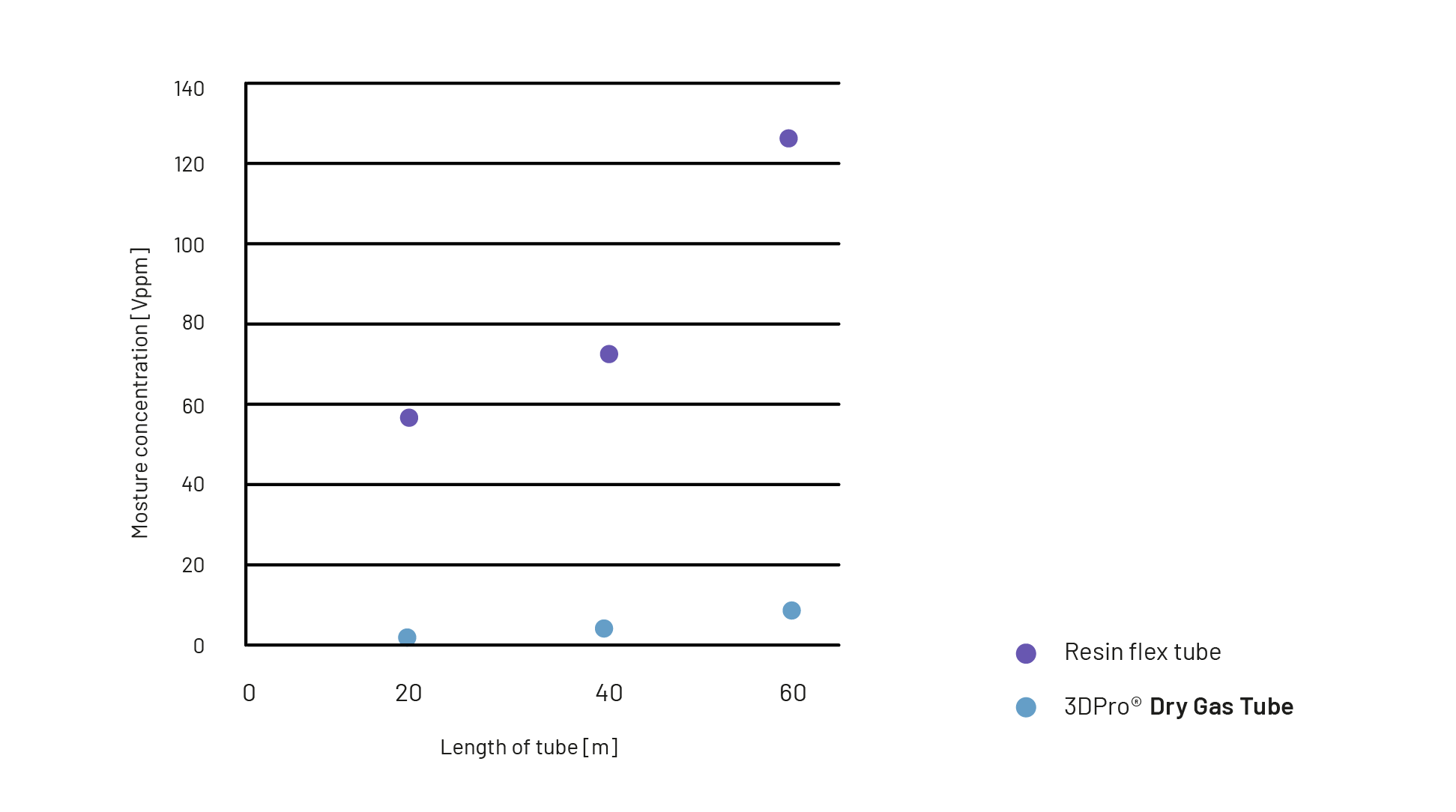

Are you sure the gas arriving at the 3D printer has the same original characteristics? The 3D printer usually is connected to the gas distribution system through flexible hoses in PTFE, which is a porous material and, therefore, permeable to air and moisture.

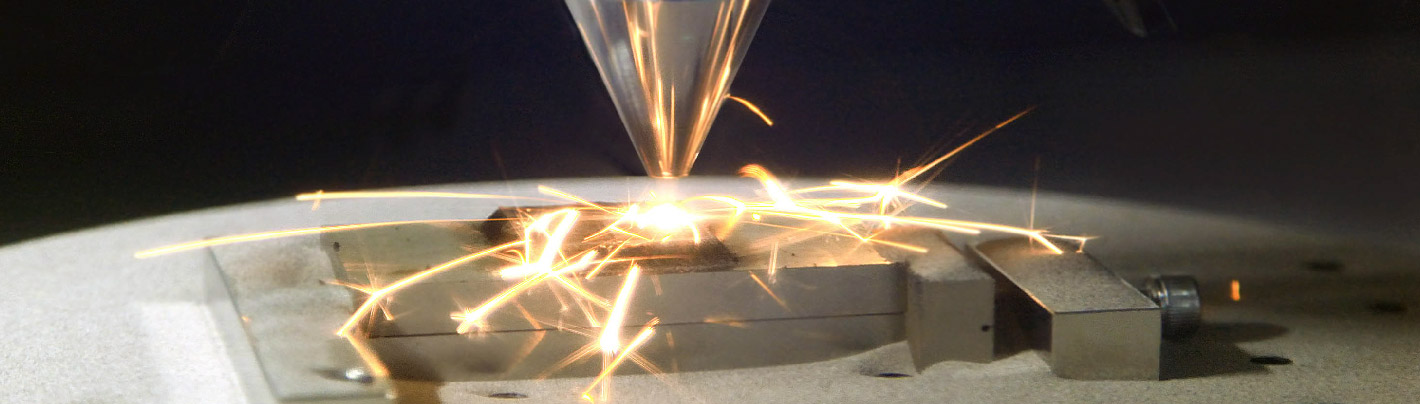

Carbon steel, stainless steel, aluminium, or titanium, just to mention a few, have different metallurgical characteristics and reactivity to air. And so, the product must be protected during the entire 3D printing process.

The presence of impurities in the protective atmosphere dueto the process itself, can generate defects in the product. Meaning the defective product is a loss. And that’s why the use of gas is essential. The gas used will be chosen according to the process and material in terms of compatibility, and we are here to advise you.