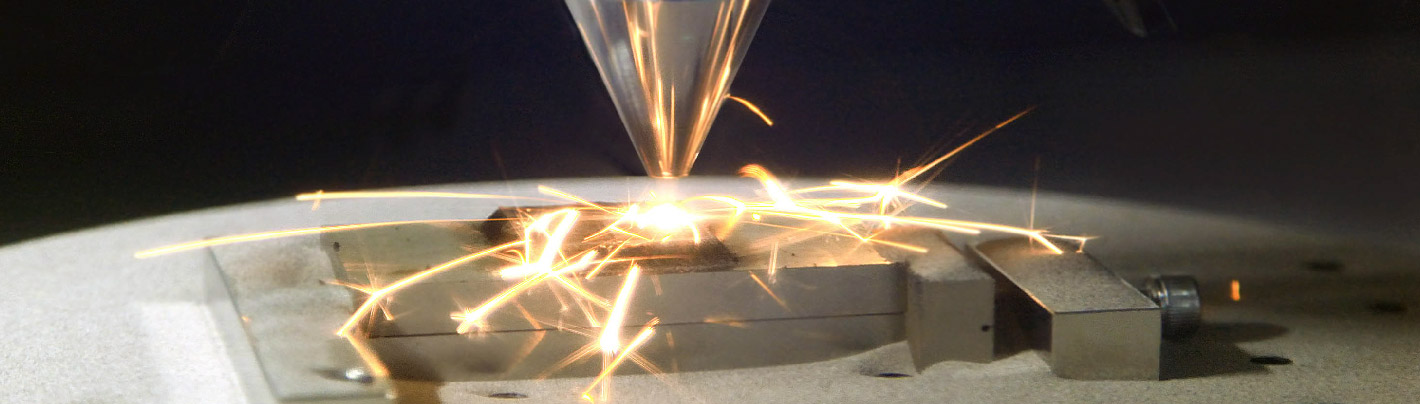

High quality gases for a very high technology process

The 3D printing process has succedeed in the last years, thanks to the development of fibre resources and a greater focus precision of the laser beam. But this is a complex process inrepeatability that still needs more studies and improvement to overcome the lack of standards.

(3DPro®)

(3DPro®)

(3DPro®)

(3DPro®)

Meaning the defective product is a loss. And that’s why the use of gas is essential. The gas used will be chosen according to the process and material in terms of compatibility, and we are here to advise you.

When supplying gas to the 3D printing process, it is essential to know the fluid dynamics. It’s fundamental to guarantee high-purity gas reaches the 3D printer unchanged.

It is of vital importance to maintain the purity of gases in the containers until being used. Nippon Gases’ passion and experience was the boost to develop specific equipment for gas management.

It is the type of the process (e.g. if an additive arc, laser, powder bed process, etc ...) and what is the gas to be used for.

It is whether the process takes place in a closed or outflow chamber, whether the same chamber is watertight or not and a study on the fluid dynamics of the same chamber.

It is whether the metallic material used is in powder or wire as the reactivity and hygroscopy of the material changes according to the shape.

Last, if the process is an FDM, the gases will be used only in the sintering heat treatment phase.

Our experts are at your disposal for technological support in all 3D metal printing processes

3D printing is in continuous and fast evolution.

We collaborate with 3D printer manufacturers, making this a state-of-art company, when it comes to emergent and experimental use of materials, having an active role in the development of processes.

Testing