More stringent NOx regulations in EU with new BAT AEL for NOx

Cost-effective NOx mitigation technology for air-fired furnaces by using small volumes of a secondary oxidant.

Tª Increase

No flue gas temperature increase

Mitigating NOx emissions by using oxygen

A low cost, low maintenance option that can be installed on allair-fired end-port regenerative glass furnaces

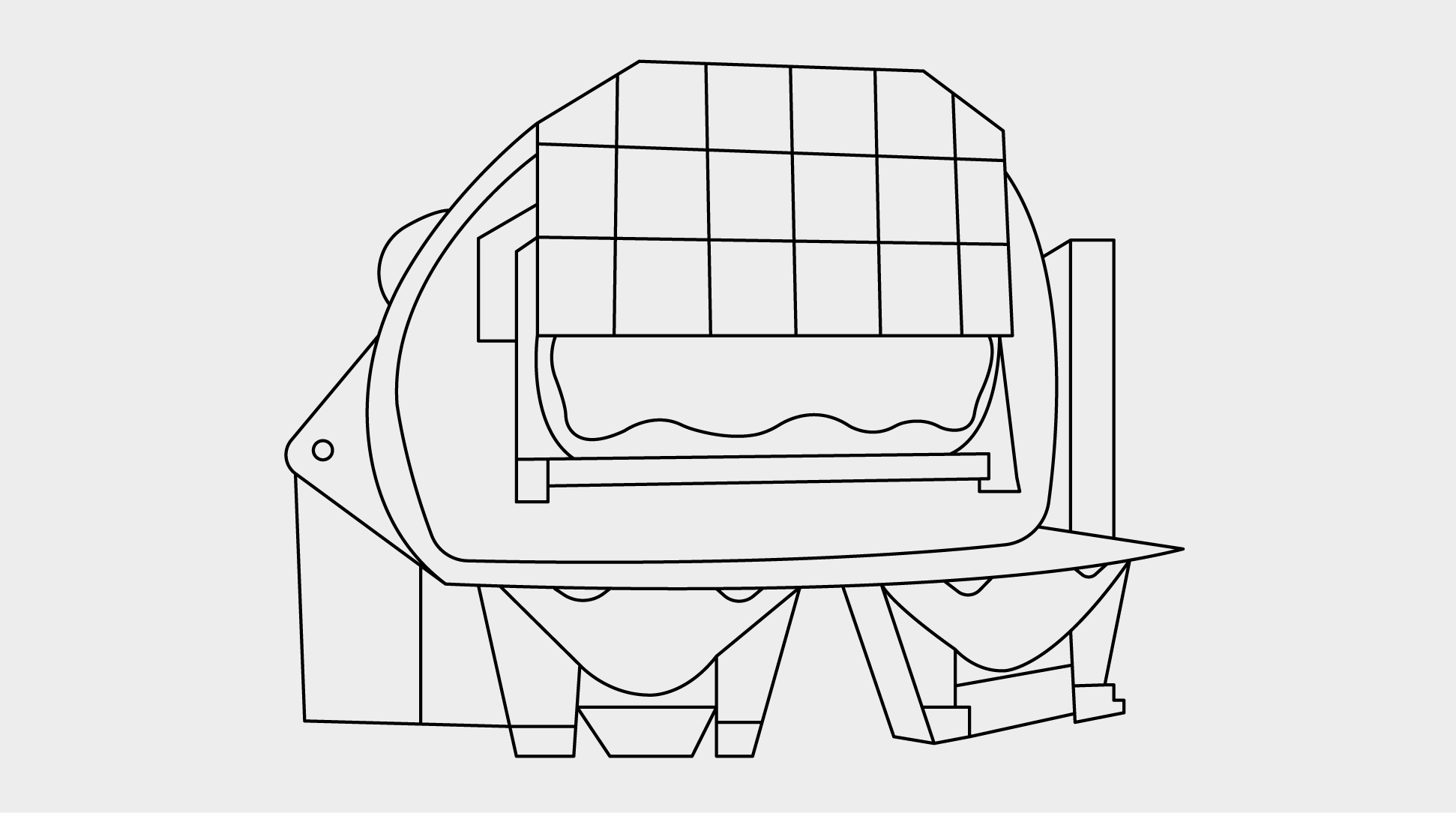

O.E.N.R. technology uses CFD modeling to optimise burner/lancing design and position to reduce NOx emissions.A two-stage combustion is promoted to get adequate levels of NOx.

Compelling technical alternative to conventional air staging or oxygen-enriched air staging for NOx reduction

Stoichiometric

ratio

adjustment

ratio

adjustment

Two-stage

combustion is

promoted

combustion is

promoted

Not to create

hot spot on the

crown

hot spot on the

crown

Possible reduction

of 3-5% fuel

consumption

of 3-5% fuel

consumption

Minimum flame

disturbance

disturbance

Temperature

profile mostly

unchanged

profile mostly

unchanged

The solution for

large

productions

large

productions

Reduce NOx

emissions

emissions

Slide to see more

Do you still have questions?

In Nippon Gases we have developed various qualities of gases to adapt to your applications. Call us or write to us and we will help you get the most out of it.