Competence on laser process

Cutting and welding sheet metal through the laser process requires gases and mixtures of high purity and production precision. Nippon Gases, through decades of experience in the production of gas,and in collaboration with the best manufacturers of laser systems, has developed production techniques capable of meeting the strictest requirements of manufacturers and beyond.

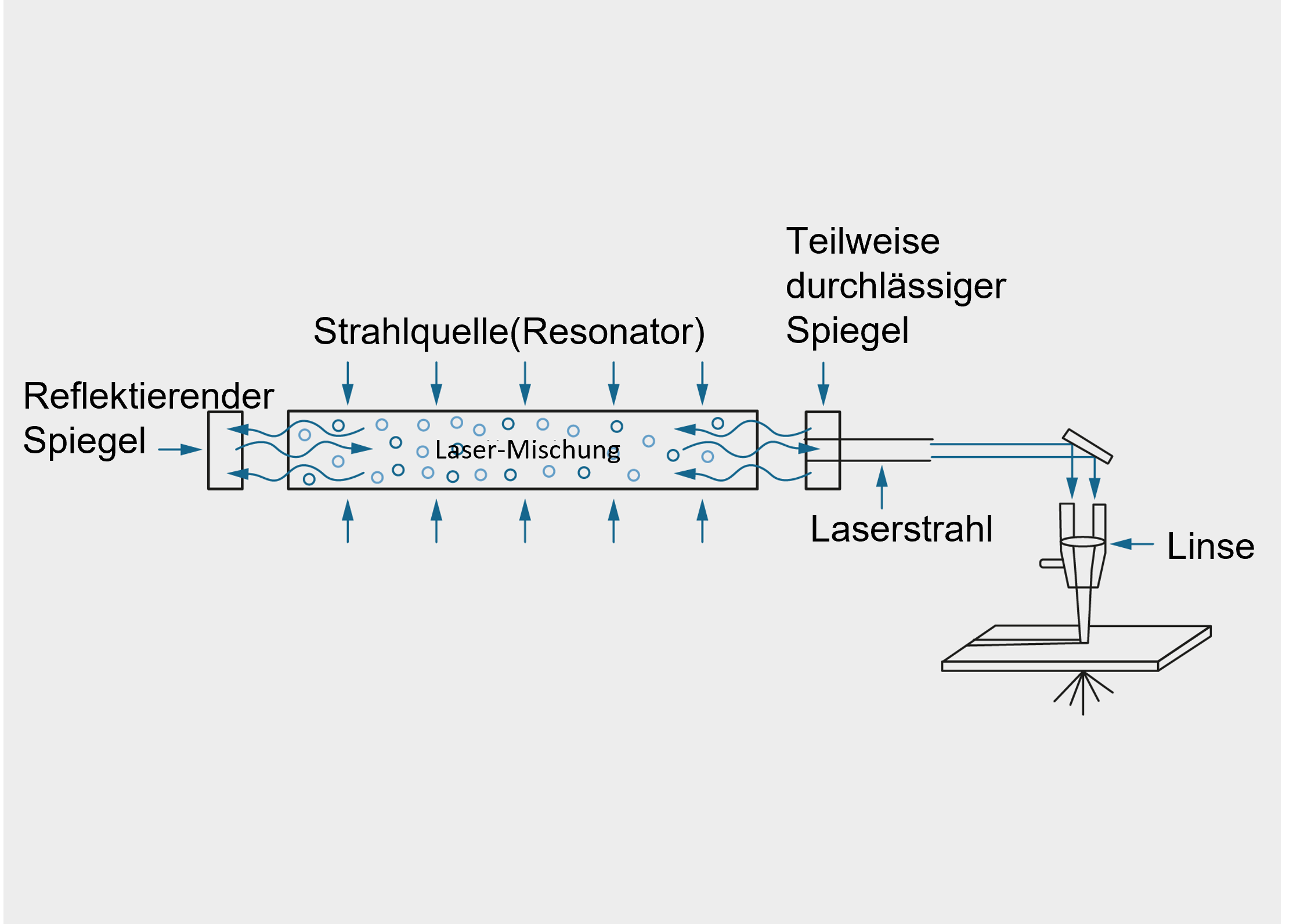

CO2 have a responsibility to create light emission for effect of energy excitation, that after polarisation, became laser beam.

The job of this gas is double, it is used to blow the molten metal out of the kerf and supports the CO2 laser as a resonator auxiliary gas in raising the energy level of the CO2 molecules.

Used into the laser source, the effect is to maintain system cooled.

For laser cutting of unalloyed steel, oxygen is necessary for the oxidation of the heated metal in the kerf, the gas also blows the molten and oxidised metal out of the kerf.

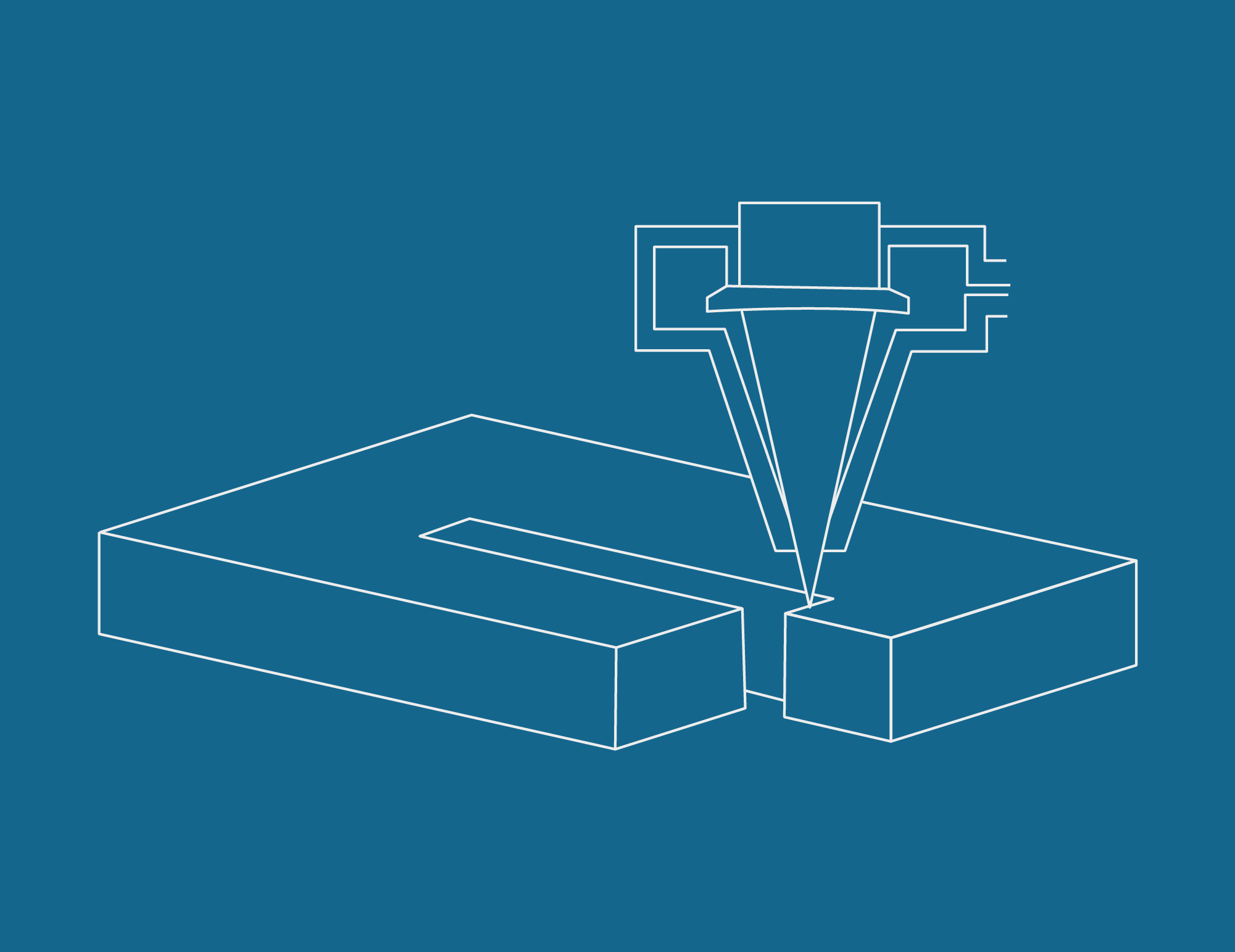

Metal reactivity

Every single material requires a

specific gas or gas mixture.

Carbon steel, stainless steel, aluminum, titanium and

many others have metallurgical different characteristics

and a reactivity towards air.

During the laser cutting or welding phases it is essential

to protect or bring heat to allow the process, while the

absence of pollutants allows to exploit all the power of

the laser sources, whether CO2 or fiber.

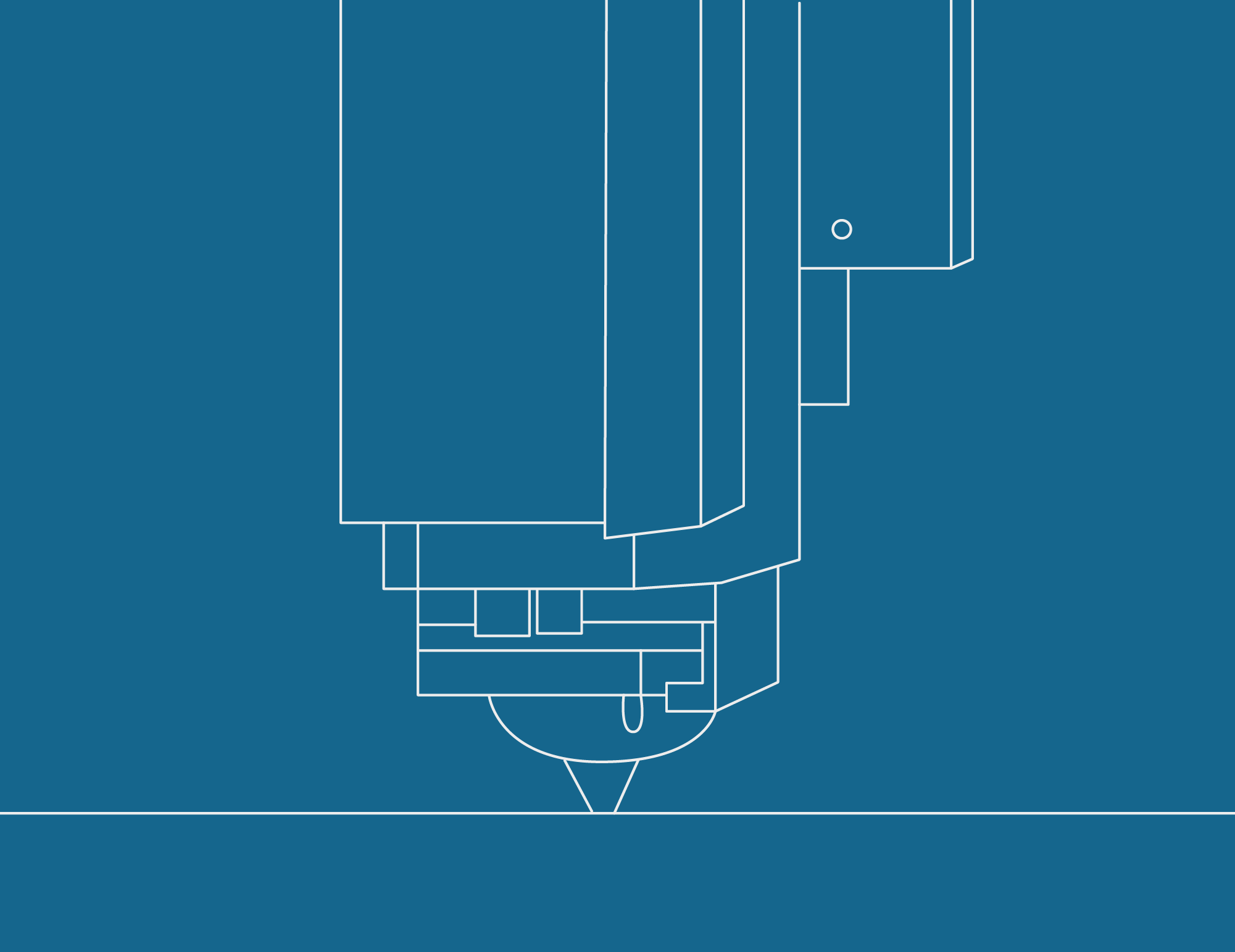

To supply gas to a laser cutting system it is essential to know fluid dynamics. In fact, it is essential to guarantee high flow rates at high pressures without affecting the machine with pressure changes.

It is equally important to maintain the purity of the gases contained in the containers up to the point of use. In this case too, the experience and passion that distinguishes Nippon Gases have allowed us to design specific equipment for gas management.

Testing