Pull rate increase, regen checkers repair and quality improvement

Air-fuel flame length control is feasable by using oxy-lancing technology that Nippon Gases can provide you.

Recuperator performance decrease

Furnace refractory repair

Quality improvement

Oxy-Fuel burners

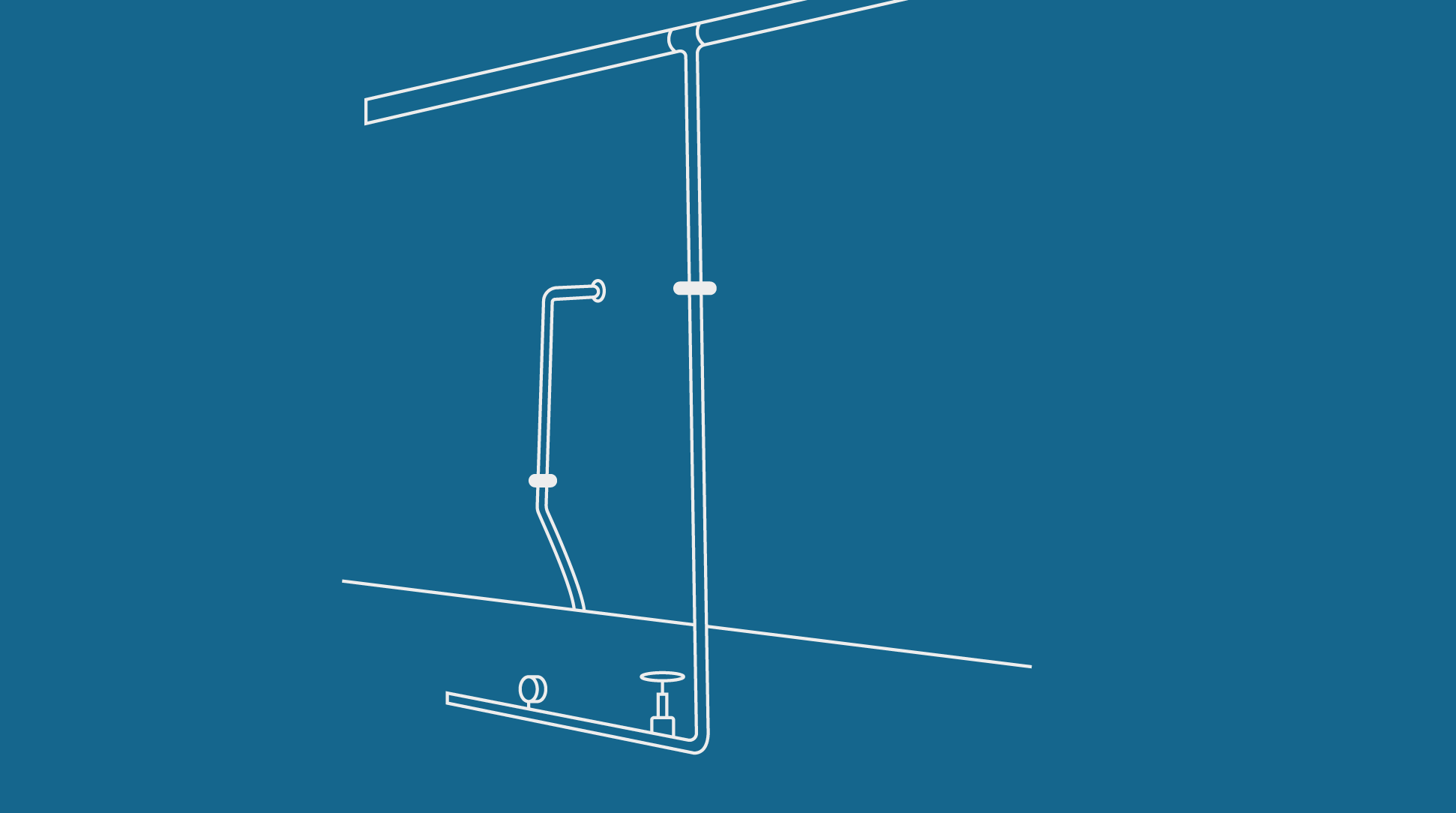

Oxygen lancing is a method where oxygen can be introduced with higher precision in locations around the air-fuel flame, where it is most required.

Oxy-lancing technology was initially used to increase the pull rate, reduce flue gas volume, and control air-fuel flame length.

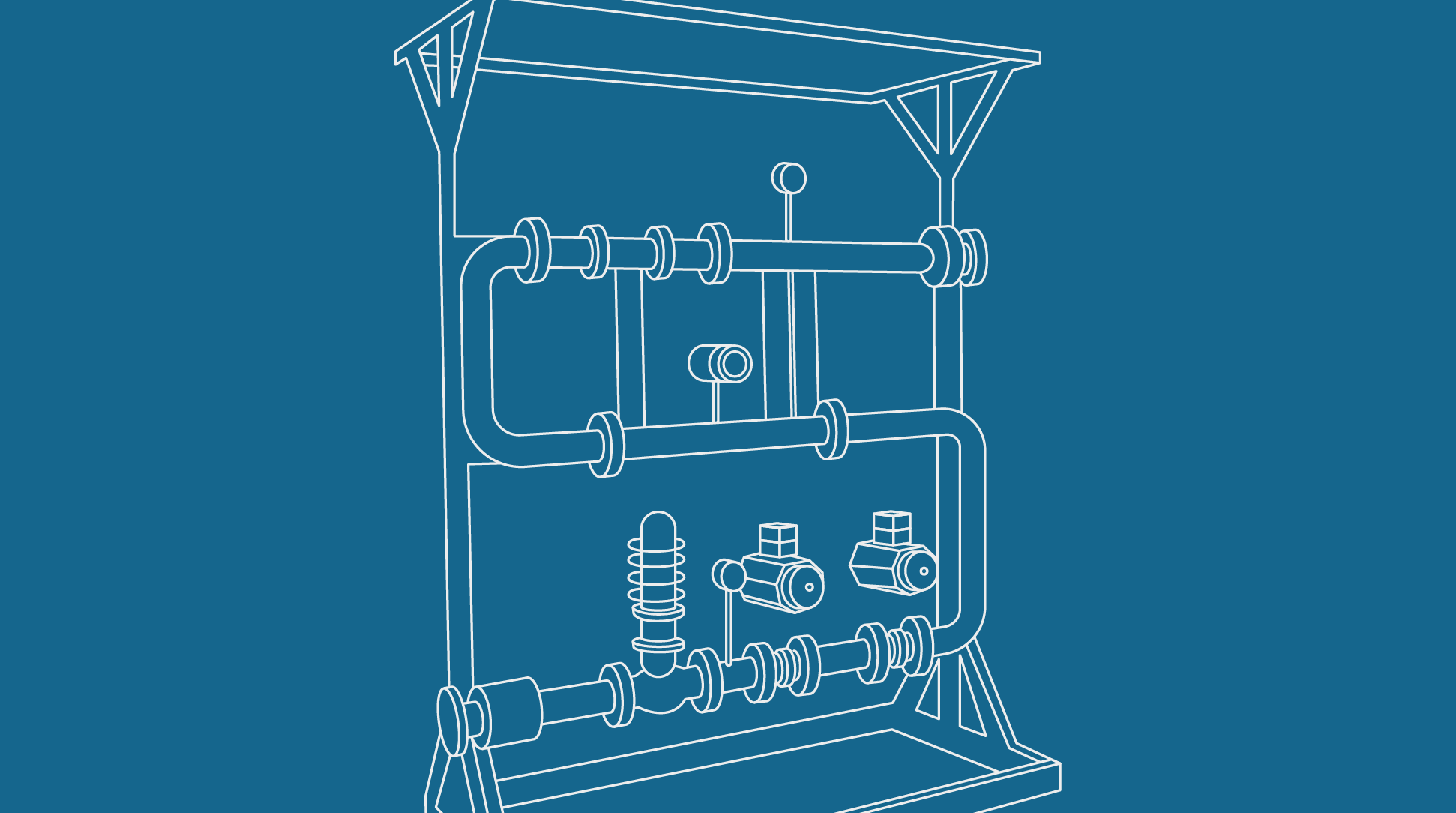

Specially designed lances/nozzles can be placed next to the under-port or throught-port fuel injectors or on the side of the port.

X

Provide the

correct amount

of oxygen

correct amount

of oxygen

X

Lower crown

temperature

temperature

X

Reduce flue gas

volume

volume

X

Adjust the flame

length

length

X

Improve

combustion

characteristics

combustion

characteristics

X

Reduce pollutant

emissions

emissions