Elevate your 3D printing process with Nippon Gases' 3DPro® Gas Line.

High quality gases for the 3D printing process

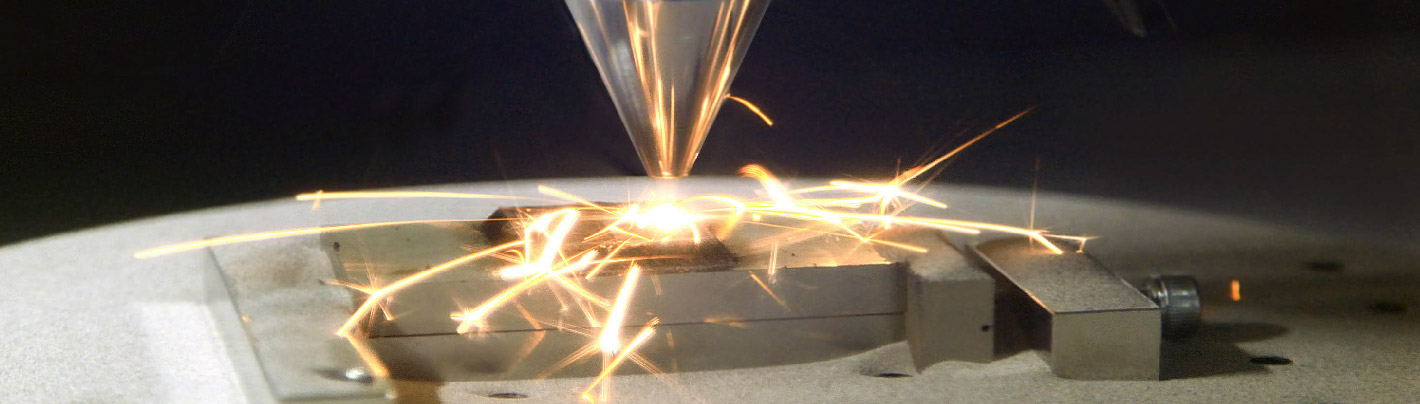

The 3D printing process has made significant strides in recent years, driven by advancements in fibre resources and laser beam precision. However, this progress has been accompanied by a complex and ongoing challenge: ensuring repeatability. Despite these improvements, the industry still faces a lack of standardised protocols and best practices, which necessitates continued research and development to achieve consistent and reliable results.

(3DPro®)

(3DPro®)

(3DPro®)

(3DPro®)

Our expert team guides you in selecting the most suitable gas for your specific application, understanding the delicate balance required for successful 3D printing with metals.

When supplying gas to the 3D printing process, it is essential to know the fluid dynamics. It’s fundamental to guarantee that high-purity gas reaches the 3D printer unchanged.

It is vital to maintain the purity of gases in the containers until they are used. Nippon Gases’ passion and experience boosted the development of specific equipment for gas management.

The specific additive manufacturing method being employed, such as arc welding, laser sintering, or powder bed fusion, plays a significant role in determining the appropriate gas and its intended use.

Consider whether the process occurs in a closed or open chamber, and whether the chamber is airtight. Additionally, understanding the fluid dynamics within the chamber is essential for optimal gas performance.

The form of the metallic material being used, whether in powder or wire, affects gas reactivity and hygroscopic properties. Different shapes can influence how the material interacts with the gas during the process.

In the case of Fused Deposition Modeling (FDM), gases are typically utilised only during the sintering and heat treatment phase, emphasising the importance of timing in gas application.