3DPro® Metal Cabinet for Additive Manufacturing Process

Competent and professional customer service

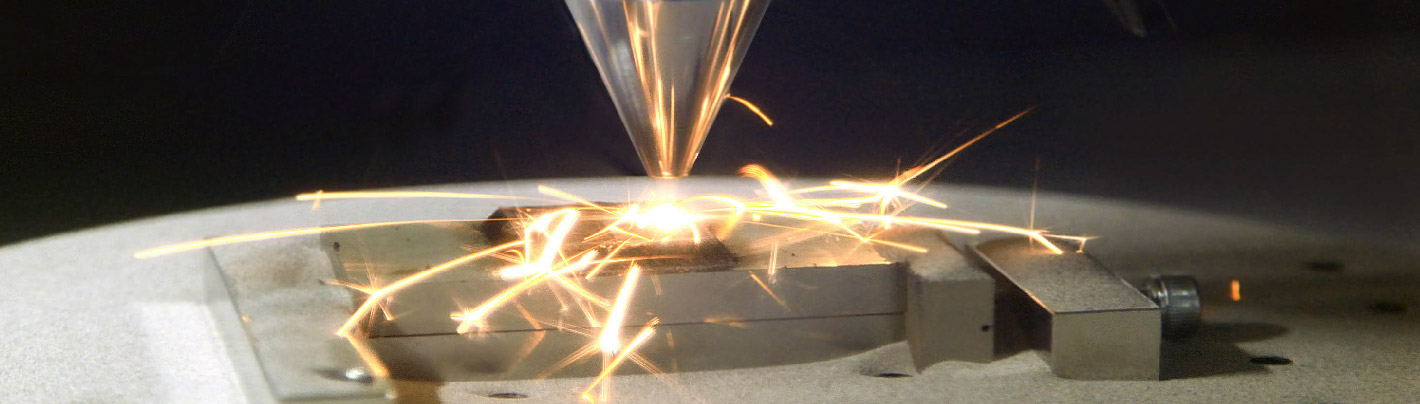

The 3D printing process has advanced significantly in recent years due to the development of fibre resources and enhanced laser beam precision. However, achieving consistent repeatability remains complex and requires further research and improvements to address the lack of standards.

30

years

of this technology

5

minutes

to open the cabinet, a month to monetise the metal powder and close it

1

month

to monetise the gas released

Over a century of experience in the various production processes in the service of additive manufacturing.

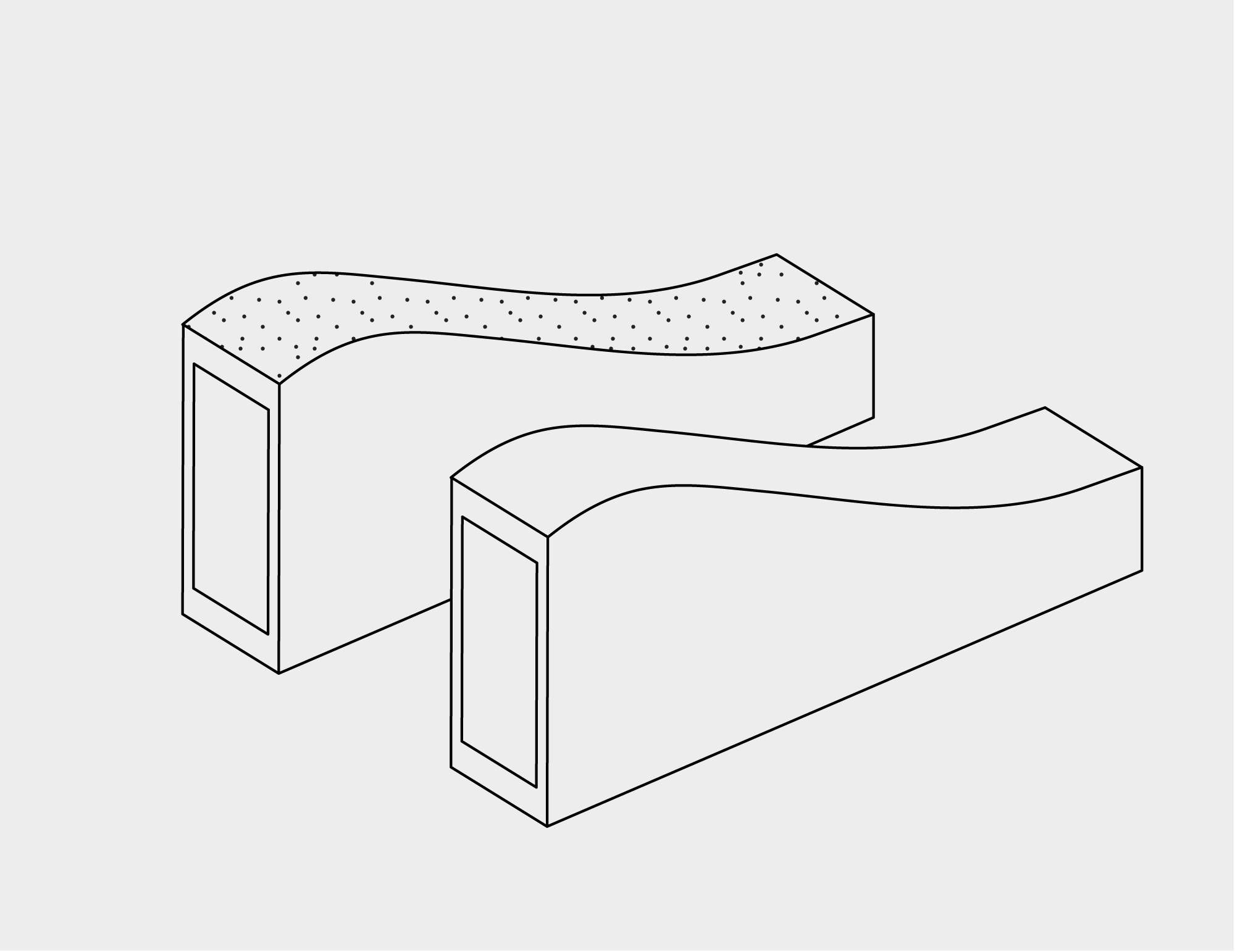

3DPro® Cabinet

Nippon Gases has developed the 3DPro® Cabinet to significantly reduce product defects caused by oxygen and moisture. By eliminating these factors, the process becomes more stable and standardised.

This cabinet ensures the protection of metal powder through its design, which maintains a constant flow of inert gas. The gas flow is deactivated when the cabinet is opened to remove metal dust and reactivated when the door is closed. Additionally, the cabinet features heated support surfaces that draw out moisture from the dust, which is then eliminated through the controlled inert gas flow.

Oxygen and Humidity: Enemies of 3D Printing

It’s widely recognised that oxygen is a contaminant that must be eliminated throughout the entire 3D printing and finishing process.

However, it’s less known that humidity can also negatively impact these processes, sometimes even more so than oxygen. Both oxygen and humidity must be removed to ensure optimal results in 3D printing.

R&D

Our R&D centers have conducted numerous studies demonstrating how oxygen and humidity cause imperfections in the metallurgical structure of 3D-printed products. These studies revealed that the presence of these contaminants inside the chamber is directly proportional to the number of defects in the final product.

The 3DPro® Powder Dry Cabinet provides a concrete solution for protecting metal powders from atmospheric contamination before the printing process. It ensures the necessary conditions to achieve effective results throughout the entire process.

Metal Power

Metal powders are normally supplied in inertised containers and as these are opened, the material comes into contact with air.

Metal powders are very susceptible to absorbing oxygen and are hygroscopic due to their properties, spherical shape and particle size.

Metal Additive Manufacturing process

The influence of gases in the

metal additive manufacturing

process.

3D printing processes can be of different types: PBF, EBM, DED, FDM, and the most recent one WAAM. There are also many different metals, often noble ones, that can also be processed, reason why this is an expensive process. All these different processes have a common characteristic, which is to protect the manufactured product from oxidisation during construction and heat treatment phases.

The influence of gases in the

metal additive manufacturing

process.

3D printing processes can be of different types: PBF, EBM, DED, FDM, and the most recent one WAAM. There are also many different metals, often noble ones, that can also be processed, reason why this is an expensive process. All these different processes have a common characteristic, which is to protect the manufactured product from oxidisation during construction and heat treatment phases.

So, to preserve the metallurgical characteristics of the metal powder essential to obtain the finished product, it is important to use high-quality gas.

We are here to help

At Nippon Gases we are called "The Gas Professionals" for a reason, give us a call as we are always here to help with solutions.