Competent and professional customer service

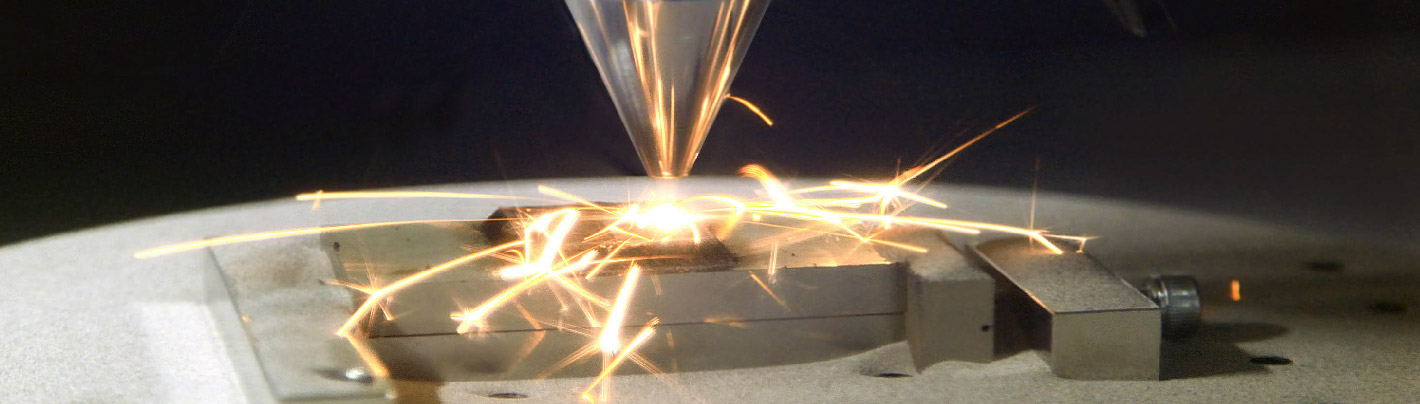

The 3D printing process has developed in the last years, thanks to the development of fibre resources and a greater focus precision of the laser beam. But this is a complex process in repeatability that still needs more studies and improvement to overcome the lack of standards.

The influence of gases in the metal additive manufacturing process.

3D printing processes can be of different types: PBF, EBM, DED, FDM, and the most recent one WAAM. There are also many different metals, often noble ones, that can also be processed, reason why this is an expensive process. All these different processes have a common characteristic, which is to protect the manufactured product from oxidisation during construction and heat treatment phases.

So, to preserve the metallurgical characteristics of the metal powder essential to obtain the finished product, it is important to use high-quality gas.

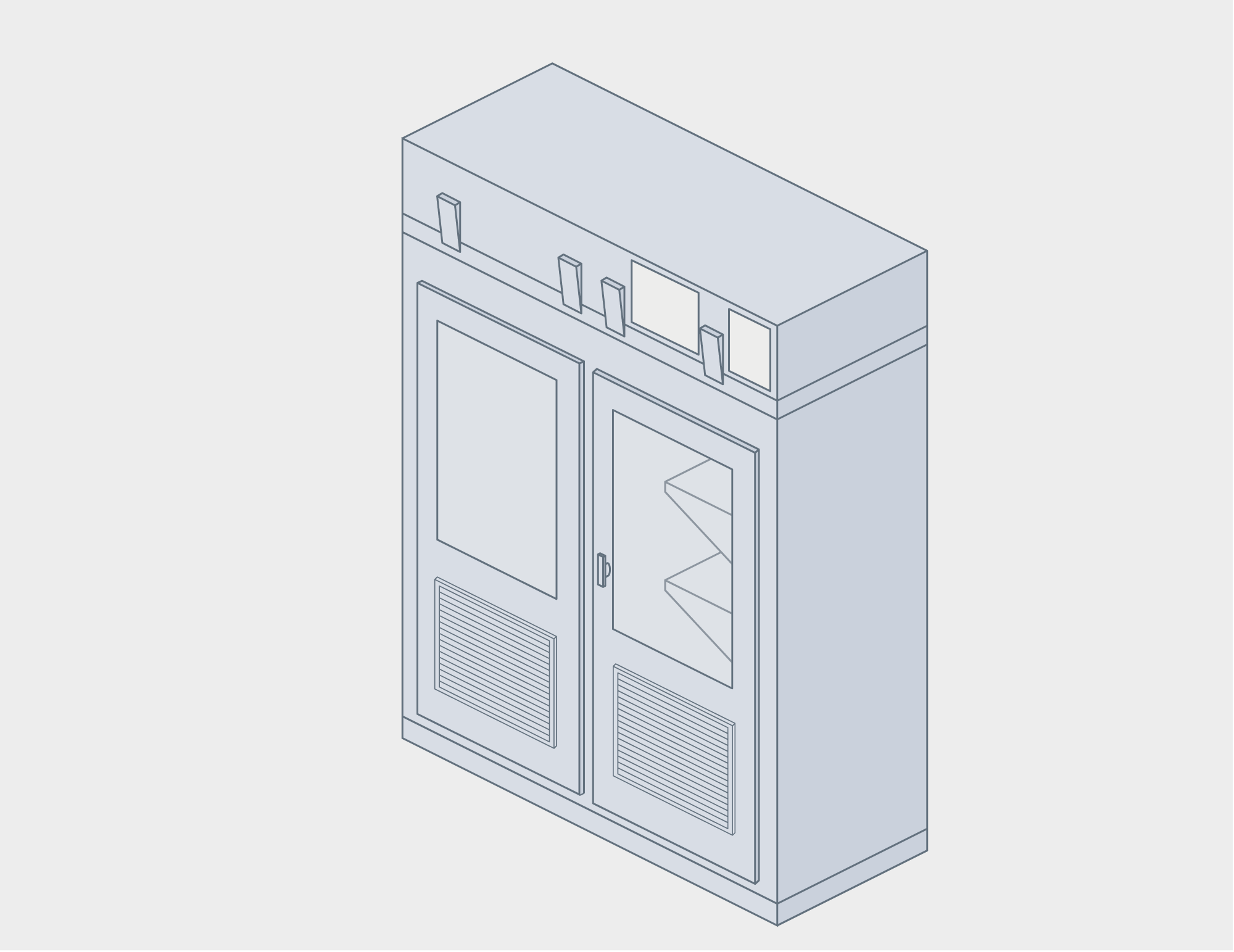

3DPro® Recirc is a recirculation purification system for PBF 3D printer

This system is integrated into a 3D printer; it eliminates impurities generated by the laser process, such as welding fumes, spatters, and oxygen and moisture derived from metal powders.

This system has many other advantages: reducing the purifying time, less gas consumption, and stabilising the 3D printing process.