Enhance meat quality and reduce wastage with CryoSan® crusting solutions.

Reduce wastage and achieve a better quality result by simplifying the process of cutting products such as meat.

This method consists of giving the food a quick cold shock with liquid gas (nitrogen/carbon dioxide). Only the surface of the food becomes hard or frozen. This is called crusting.

Advantages of using liquid gas for crusting the surface of meat

- Best way to have a flexible and productive freezing line.

- High-quality end product.

- Easy to increase production capacity when needed.

- Avoid weight loss due to dehydration. It does not organoleptically modify the meat.

- Better microbiological quality. Multiple applications.

- Higher productivity. Extends the life of the blades.

Shell freezing or crusting

improves filleting quality.

The preparation of the pieces is streamlined, it is not necessary to have them several hours in chambers before cutting.

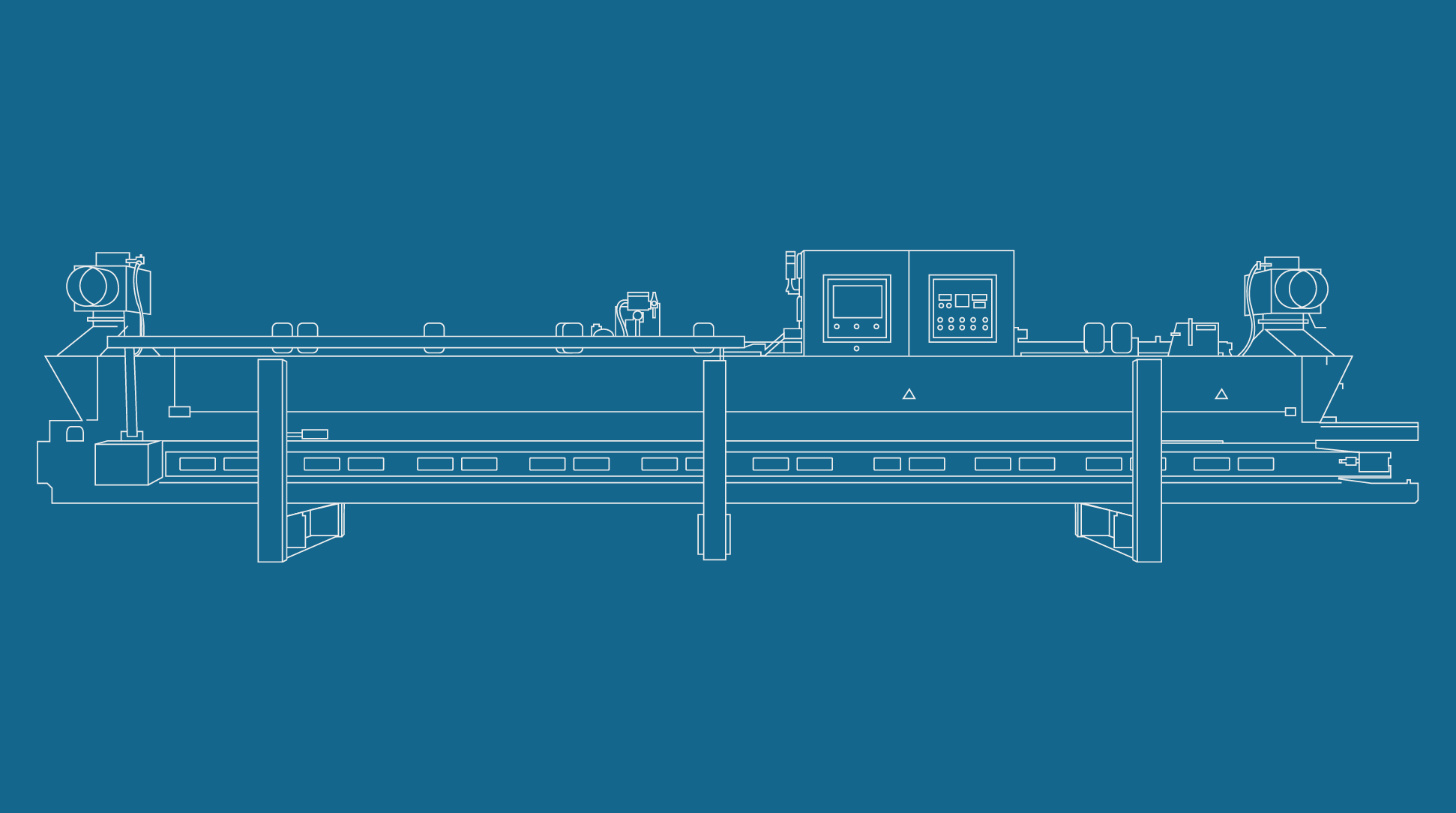

Cryogenic Cabinet

A flexible solution.

Use liquid carbon dioxide (LCO2) or liquid nitrogen (LIN) and discover how versatile the gas is in combination with our cryogenic equipment, capable of meeting a number of production needs.

Take advantage of the properties of carbonic snow and cool, inertise and protect your food with the bacteriostatic power of CO2.

For portable use or coupled with some kneading equipment.

Cryogenic Test Cabinet

Try cryogenics without compromise.

Our portable test equipment is equipped with wheels and is small in size. It allows you to perform real tests in your own facilities with any of our portable supplies. It verifies the quality of the product, determines the needed working parameters and confirms the estimates of cryogenic gas consumption.

- Stunning

- Freezing

- Wrapped

- Blow cold

- Mixer

- Freezing

- Wrapped

- Glazed

- Blow cold

- Freezing

- Packing

- Blow cold

- pH control

- Freezing

- Chilling

- Packing

- Blow cold

- Freezing

- Blow cold

- Mixer

Testing