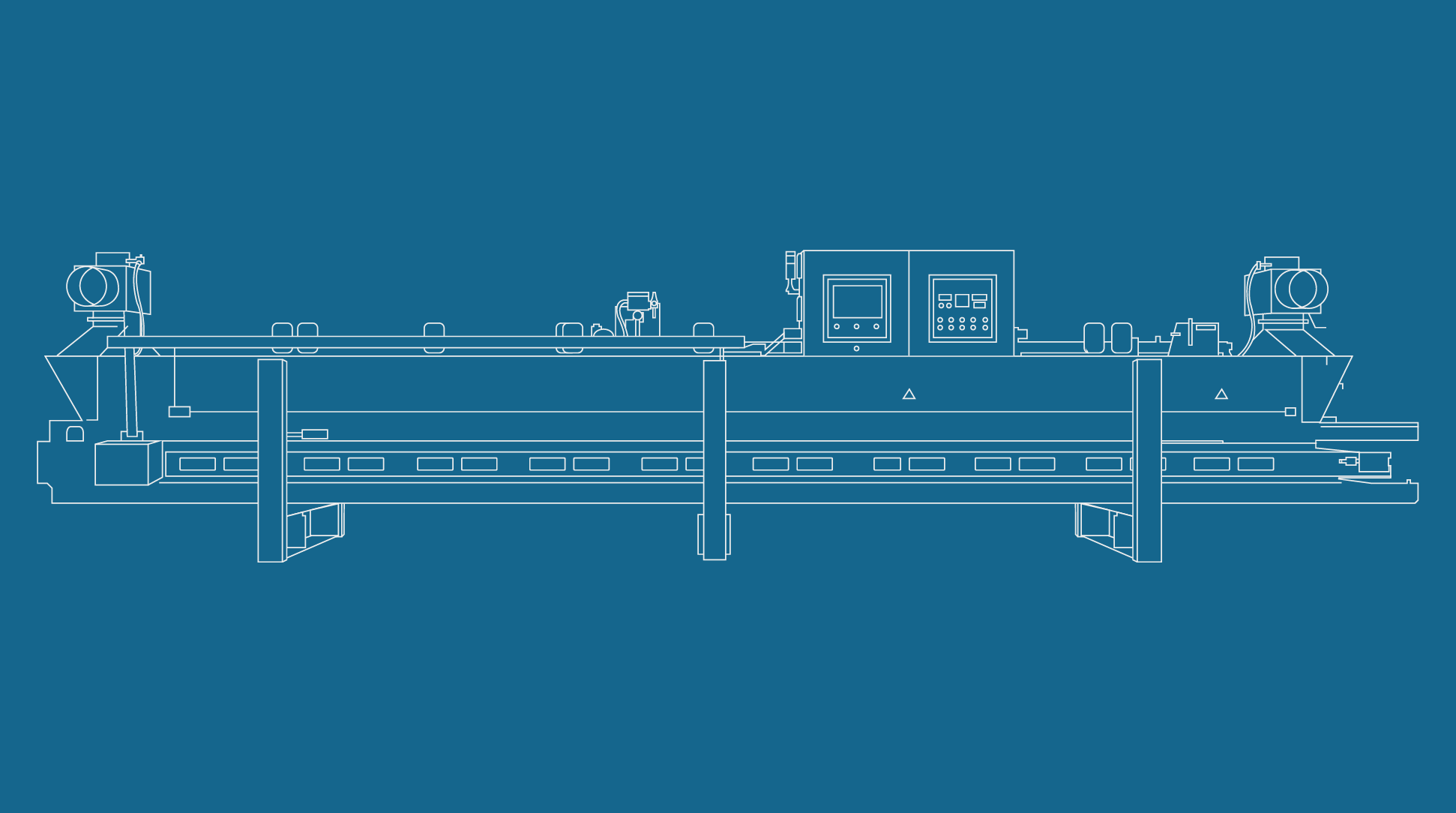

Freezing and chilling cryogenic solutions

Cryogenic is the best way to freeze your product. Higher quality, higher production rate, higher performance and flexibility.

Our wide range of solutions fits any industrial process while adapting to the type and size of the product.

Reduction of losses, economic impact, in the same space as traditional tunnels.

- Protecting coat

- Non-continuous cabinet

Cryogenic cabinet

Adapted to your rhythm

Work with LCO2 and discover the versatility of the

gases in our cryogenic equipment, capable of meeting

production needs in a wide range of values.

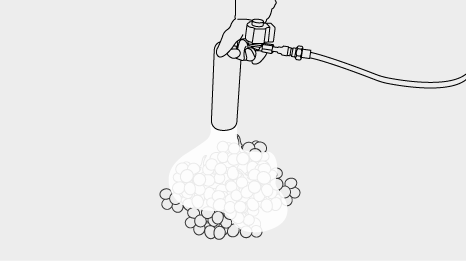

Take advantage of the properties of carbonic snow and cool, inertise and protect your food with the bacteriostatic power of CO2.

For portable use or coupled with some kneading equipment.

Cryogenic test cabinet

Try cryogenics without

compromise.

Our portable test equipment is equipped with wheels, is

small in size and can be adapted to LCO2. It allows

you to perform real tests at your own facilities with any

of our portable supplies. It verifies the quality of the

product, determines the needed working parameters

and confirms the estimates of cryogenic gas

consumption.

capacity when needed.

- Stunning

- Freezing

- Wrapped

- Blow cold

- Mixer

- Freezing

- Wrapped

- Glazed

- Blow cold

- Freezing

- Packing

- Blow cold

- pH control

- Freezing

- Chilling

- Packing

- Blow cold

- Freezing

- Blow cold

- Mixer

Testing