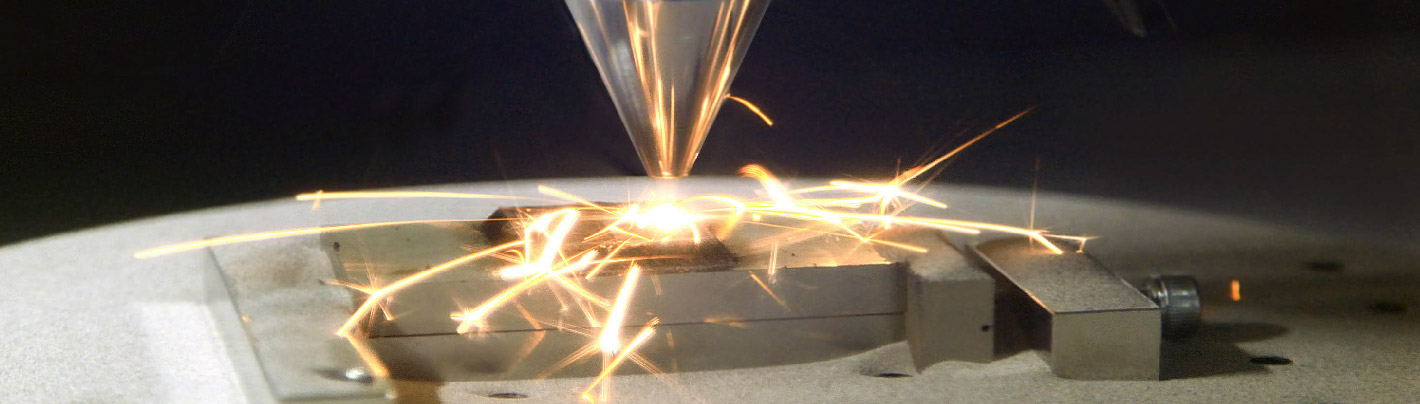

Discover Nippon Gases' specialised solutions for additive manufacturing.

Gases we use

The PBF process commonly use nitrogen with materials like stainless steel, or Argon for other types of materials. We can help you analyse what is the best performing mixture for your DED or PBF process. Another gas solution is helium, which is used in the EBM process, although being expensive for this process, it consumes a little amount.

On the other hand, the FDM process uses argon/nitrogen and small percentages of hydrogen in argon, but only in the metal sintering phase. For further information don’t hesitate to contact us.

On the other hand, the FDM process uses argon/nitrogen and small percentages of hydrogen in argon, but only in the metal sintering phase. For further information don’t hesitate to contact us.

Do you still have questions?

At Nippon Gases we are called “The Gas Professionals” for a reason, and it’s because we’ll be able to solve any doubt.